From Molecule to Market: The AI-Driven Future of Product Formulation

How Life Sciences and CPG companies are using generative molecular design and causal inference to accelerate R&D timelines by 50%.

The Traditional R&D Bottleneck

Developing a new pharmaceutical compound or consumer product formulation traditionally takes years and costs millions. Most candidates fail. The process is iterative, expensive, and slow.

AI is fundamentally changing this equation.

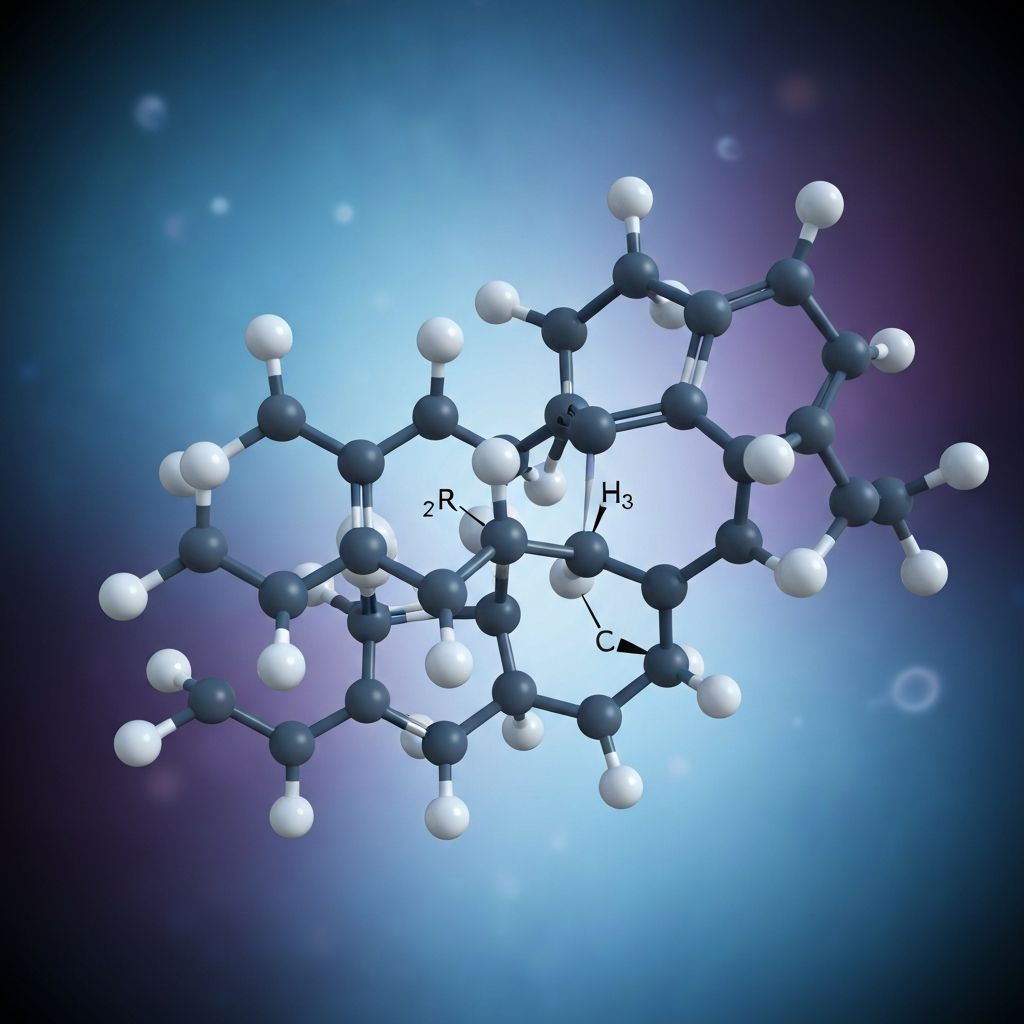

Generative Molecular Design

Modern AI can generate novel molecular structures with desired properties:

- Drug Discovery: Generate small molecules that bind to specific protein targets

- Material Science: Design polymers with precise thermal/mechanical properties

- Cosmetics: Create formulations that balance efficacy, stability, and sensory experience

The Technical Stack

We combine multiple AI paradigms:

- Generative Models: VAEs, GANs, and diffusion models to explore chemical space

- Property Prediction: Graph neural networks (GNNs) for ADMET prediction

- Active Learning: Iteratively select most informative experiments

- Causal Inference: Understand structure-property relationships, not just correlations

Causal Analysis: The Secret Weapon

Generative models can propose thousands of candidates. Causal inference tells you why certain structures work, enabling rational design rather than blind screening.

Case Study: Optimizing a Skincare Formulation

A CPG client wanted to improve a moisturizer's efficacy without increasing irritation. Traditional approach: test hundreds of variants manually.

Our Approach:

- Built a causal model of ingredient interactions → efficacy → irritation

- Used generative AI to propose novel formulations respecting causal constraints

- Simulated outcomes before physical testing

- Lab validation of top 5 candidates

Result: 40% reduction in testing time, 25% improvement in efficacy, zero increase in irritation.

The Digital Twin Paradigm

We're moving toward digital twins of R&D processes:

- Virtual screening before physical experiments

- Predictive models for manufacturing scale-up

- Real-time optimization of process parameters

Implementation Roadmap

For organizations looking to adopt this approach:

- Data Foundation: Consolidate historical R&D data (structured and unstructured)

- Modeling Infrastructure: Build cloud-based platforms for large-scale simulations

- Workflow Integration: Connect AI tools to lab equipment and ELN systems

- Validation Protocol: Establish rigorous testing of AI predictions against ground truth

The Competitive Advantage

Early adopters are seeing dramatic improvements:

- 50-70% reduction in time-to-market

- 30-50% reduction in R&D costs

- Higher success rates (fewer failed candidates)

- Novel products that couldn't be discovered through traditional methods

The future of product development is not just faster—it's fundamentally different. AI doesn't just accelerate the old process; it enables entirely new ways of innovating.

Sean Li

Founder & Principal Consultant at Duoduo Tech. Specializes in production-grade AI infrastructure, causal inference, and domain-specific ML applications across Life Sciences, Finance, and Media.